From New Zealand to Your Home

MNZ controls the entire process from hive to finished product, ensuring quality, purity and integrity at every stage. From responsible beekeeping to careful production and packaging, each step is managed under strict New Zealand standards.

All laboratory testing is carried out in ISO 17025 accredited laboratories recognised by IANZ. Storage, processing and packaging operate under a Registered Risk Management Programme (RMP) in accordance with the requirements of the New Zealand Ministry for Primary Industries (MPI). This guarantees a controlled and fully traceable supply chain.

Extensive authenticity and quality testing is conducted both at raw material stage and on the final product. MNZ produces exclusively raw, unfiltered and unpasteurised monofloral MGO Manuka honey.

Manuka Honey Process

Manuka honey is produced in New Zealand during the short flowering period of the native Manuka tree. For only a few weeks each year, bees collect nectar from the blossoms, creating this rare and distinctive honey.

After harvesting, the honey is carefully extracted from the honeycomb and immediately subjected to quality testing. It is stored at controlled natural temperatures (below 25°C) to preserve purity. When preparation for packing begins, the honey is gently warmed in controlled conditions up to a maximum of 35°C. This ensures optimal texture without compromising its natural characteristics.

The honey is then packed and labelled according to its verified MGO level. A final quality check is performed before release. Because all stages are managed in-house, MNZ maintains full control over the entire production process.

Extensive Quality Testing

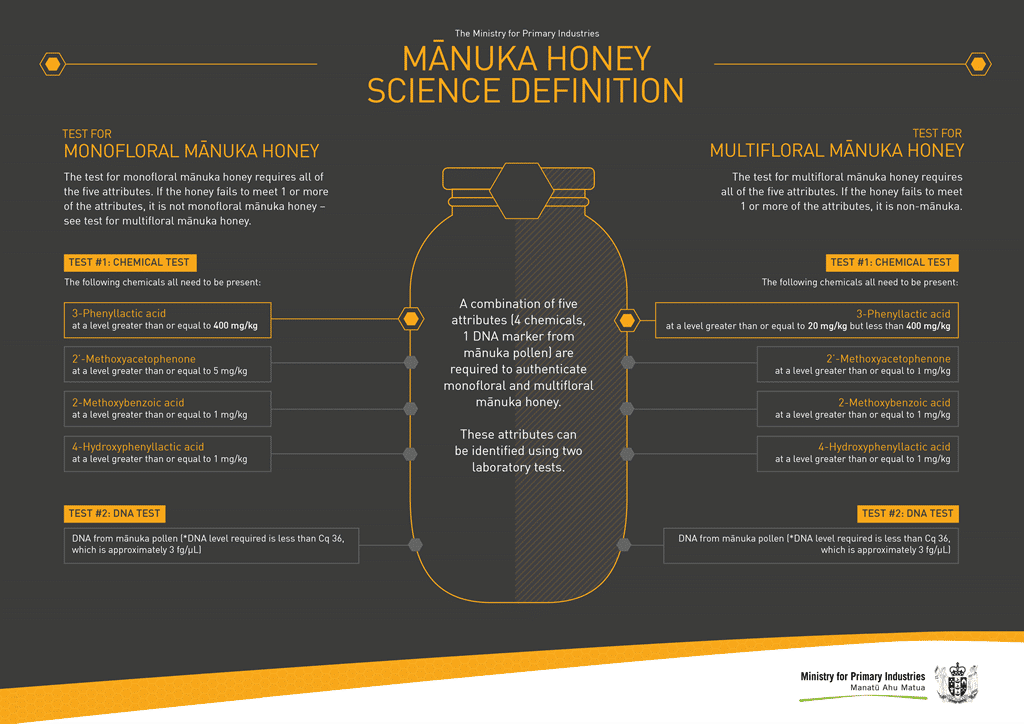

Monofloral Manuka honey requires careful handling, as it is particularly sensitive to heat and processing conditions. All MNZ testing procedures follow the official MPI guidelines to ensure authenticity and compliance.

Step 1 – Authenticity Verification

Each batch is tested according to the MPI definition for Manuka honey. Five scientifically defined markers must be present to classify honey as monofloral Manuka.

Step 2 – Chemical Markers

• 3-Phenyllactic acid

• 2-Methoxyacetophenone

• 2-Methoxybenzoic acid

• 4-Hydroxyphenyllactic acid

Step 3 – DNA Analysis

• DNA confirmation of Manuka pollen

Step 4 – MGO Testing

Methylglyoxal (MGO) is one of the key compounds measured in Manuka honey. Its concentration determines the MGO classification. Testing for MGO content is a requirement under MPI standards and is verified through laboratory analysis.

Step 5 – Additional Quality and Safety Tests

To ensure purity, freshness and safety, each batch is tested for:

• Diastase activity

• Hydroxymethylfurfural (HMF)

• C4 sugars (adulteration control)

• Aerobic plate count

- 대장균

- 수분 함량

- Tutin

- 피롤리지딘 알칼로이드(PA)

• Yeast and mould

- 황색포도상구균

• Total coliforms

MPI(뉴질랜드 1차 산업부) - 마누카 꿀의 정의

뉴질랜드의 MPI는 마누카 꿀이 단일 꽃꿀인지, 아니면 복합 꽃꿀인지를 판단하는 명확한 가이드라인을 마련했습니다. MNZ는 단일화분 MGO 마누카꿀만을 생산합니다.