With so many different brands and types of Manuka honey, it can be difficult to know which ones are good and which are not. As producers of Manuka honey, we find it concerning that there is a lot of fraud causing people to lose confidence in the product and its health benefits. This is why we want to educate you on what to look out for before buying Manuka honey. Below, you will first find an overview of all the points you should pay attention to, and afterward, we will go into more detail about each point and explain why it is important.

WHAT TO LOOK OUT FOR WHEN BUYING MANUKA HONEY

MGO VALUES, FRAUD AND HEATING

How can I determine if the Manuka honey is not completely authentic and if the MGO values are correct?

- You can recognize counterfeit Manuka honey by the fact that it is often much cheaper than other brands with similar products.

- Authentic Manuka honey should be packaged and processed in New Zealand, as New Zealand has strict requirements for the production of Manuka honey.

- Missing Made in New Zealand logo.

MANUKA HONEY IS NOT CREAMED HONEY (CREAMED HONEY IS PROCESSED HONEY).

Manuka honey naturally has a thicker and more textured consistency compared to floral honey, which is generally stiffer and less runny. However, if the honey is very smooth and runny, this could indicate that it has been processed, possibly making it a creamed Manuka honey.

PACKAGED AND PROCESSED IN NEW ZEALAND.

Because New Zealand has and sets strict requirements for the processing and production of Manuka honey, the chance of fraud or tampering with the honey is significantly lower in New Zealand than outside it. Therefore, it is important that the Manuka honey is also packaged and processed in New Zealand. If the honey is packaged outside New Zealand, there is a possibility that it could be tampered with afterwards, as other countries generally have less stringent requirements for Manuka honey than New Zealand.

GMO FREE, CHEMICAL FREE AND NO PESTICIDES USED SUCH AS GLYSOPHATE ETC….

Pure nature; no chemicals or other undesirable substances.

More about GMO and Glyphosate -->

MONOFLORAL (INDICATED ON THE LABEL).

With Manuka honey, “monofloral” means that it comes exclusively from one type of blossom and is pure Manuka honey, not mixed with other types of honey.

PACKAGING BPA FREE (INDICATED ON LABEL)

BPA can affect the quality of the honey and has been shown to be harmful to your health.

MGO VALUE VS UMF

UMF is a summation of several factors and is therefore prone to interpretation, whereas MGO is an exact measurement of the active ingredient in Manuka honey. Because of its precision, the MGO value is now the standard for determining the strength of Manuka honey. The higher the MGO value, the more bioactive the honey is (MGO 100+ contains at least 100 mg of methylglyoxal per kg). Contrary to what many companies claim, the Unique Manuka Factor (UMF®) cannot be measured directly in the laboratory. Instead, UMF® values are calculated based on the measured concentration of methylglyoxal in the honey, as required by the relevant standards. This calculation uses published data (*) where both UMF and methylglyoxal concentrations are measured in different samples of honey. It is important to note that these calculated values and test methods are not accredited by IANZ (International Accreditation New Zealand) and make no implicit statement about the authenticity of Manuka honey. UMF values lower than 5 are estimated based on the extrapolation of the relationship between methylglyoxal and UMF.

* *Isolation by HPLC and characterization of the anti******** active fraction of New Zealand manuka honey (Leptospermum scoparium). C.J. Adams, et al. Carbohydrate Research 343 (2008) 651-659. And, corrigendum to “Isolation by HPLC and characterization of the anti******* active fraction of New Zealand manuka honey (Leptospermum scoparium)” [Carbohydr. Res.

343(2008)651]. Carbohydrate Research 344 (2009) 2609. C.J. Adams, et al.

WELL-BEING OF THE BEES

In our opinion, bees that live undisturbed in nature without any form of radiation ultimately produce the best honey. You may want to inquire with the respective producer about how they treat their bees.

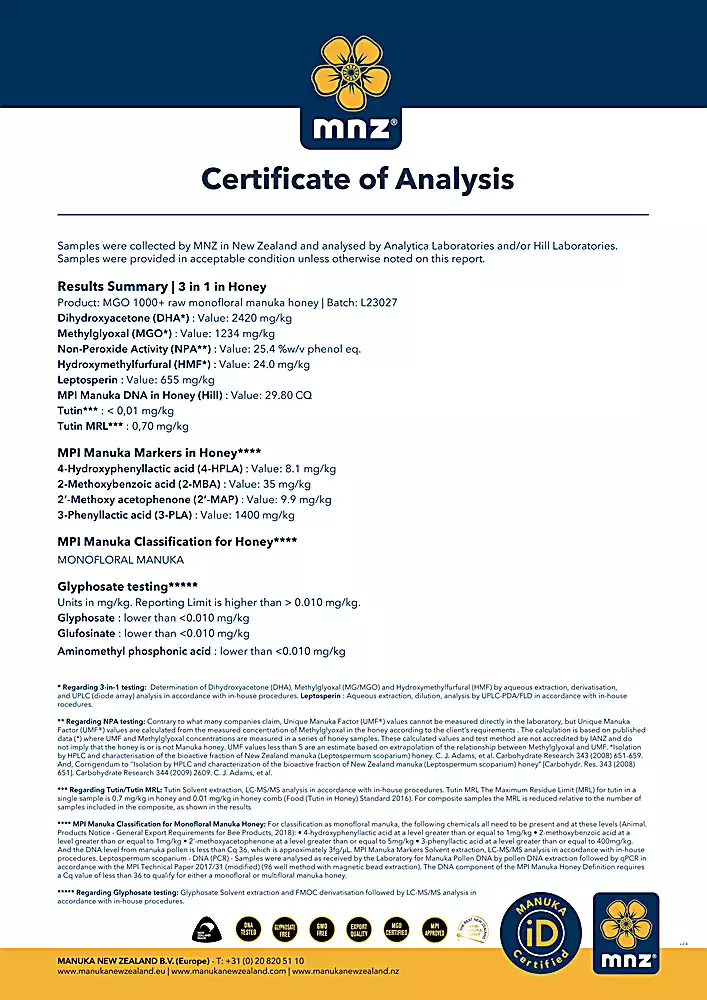

ALWAYS ASK FOR THE TEST REPORT

If you have doubts about the authenticity or possible fraud of Manuka honey, it is wise to always ask for test results. This provides assurance that the honey has not been adulterated or heated.

IS THE ENTIRE PROCESS MANAGED BY THE MANUFACTURER?

To ensure consistent quality, it is important that the entire process is in the hands of the manufacturer—from the bees, to harvesting, to processing, and packaging.

MANUKA HONEY FRAUD

Honey fraud, a growing problem in the world of food production and distribution, casts a shadow over the integrity of the honey industry and threatens the health and trust of consumers. This form of fraud includes various practices that aim to falsify or conceal the quality, origin, and composition of honey.

One of the most common forms of honey fraud is mixing honey with cheaper sugar syrups, such as corn syrup or rice syrup. This allows both the producer and seller to provide more product at a lower cost, resulting in higher profit margins. This adulteration of honey is not only economically damaging to honest beekeepers but also lowers the nutritional value and quality of the honey, as these syrups do not provide the same health benefits as real honey.

Another form of honey fraud involves the removal of pollen from honey. Pollen forms a natural fingerprint of honey’s origin and can be used to determine where honey comes from. Removing pollen makes it more difficult to determine the origin of the honey and may be an attempt to hide the origin, especially if it comes from countries with lower quality standards.

In addition, honey fraud can also involve the use of pesticides and antibiotics in beekeeping, which can result in residues in the honey. This can pose a potential risk to consumers, especially if the levels of these substances exceed legal limits.

To protect consumers from honey fraud, many countries have introduced regulations and standards to ensure the quality and origin of honey. Companies in the honey industry are increasingly urged to be transparent about the origin of their products and to conduct independent tests to prove the authenticity of their honey.

Consumers also play a crucial role in combating honey fraud by being critical when choosing their honey sources and looking for trustworthy producers who thoroughly test their products and clearly communicate their origins. Awareness of this problem and supporting honest and incorruptible practices in the honey industry are essential to maintaining the purity and quality of this beloved natural product.

At MNZ, we employ a manufacturing process that effectively prevents fraud with our Manuka honey, and this process is fully organized from hive to finished product. Our commitment to integrity and quality begins at the source, with carefully selected beekeepers who meet strict bee care and beekeeping guidelines. This ensures that our bees are healthy and well-treated, which benefits the quality of the nectar collected and ultimately the honey.

During the Manuka nectar collection process, we ensure that our bees have access to healthy and untreated Manuka bushes. This ensures that the nectar is of the highest possible quality. We avoid the use of synthetic pesticides or antibiotics in our beekeeping, which contributes to the purity of our product.

Once the honey is harvested, it is carefully extracted and processed in a facility that meets the highest standards of food hygiene and safety. This eliminates the possibility of cross-contamination.

Our strict quality control does not stop at production. We conduct extensive testing to ensure that our honey meets the strictest standards. Not only do we measure the concentration of methylglyoxal (MGO), the unique active ingredient in Manuka honey, but we also conduct pollen analysis to confirm the origin of the honey and a host of other scientific tests. This data is made public so that our customers have full insight into the origin and quality of our product.

At MNZ, we understand the importance of honesty and integrity in the honey industry, and we remain committed to effectively preventing fraud and maintaining our customers’ trust. Our process, from hive to finished product, guarantees the purity and quality of our Manuka honey.

MGO VALUES, HEATED HONEY AND FRAUD.

When Manuka honey is heated, it undergoes a color change, taking on a very dark brown hue and developing a somewhat bitter taste. This change can be measured by HMF (Hydroxymethylfurfural), an indicator of heating.

One of the most common problems in the Manuka honey industry is the heating of honey to achieve artificially higher MGO levels without the consumer’s knowledge. This practice leads consumers to believe they are buying high-quality, high-MGO Manuka honey when, in reality, they are getting cheaper honey.

MGO (methylglyoxal) is a naturally occurring compound in Manuka honey that is responsible for its unique therapeutic properties. The concentration of MGO in Manuka honey is an important indicator of its quality and potential healing power. The problem arises when producers choose to heat honey with low MGO values, resulting in an artificial increase in these values. This allows the honey to be sold at a higher price, while the consumer does not experience the expected benefits of real Manuka honey.

This practice is not only misleading but also undermines consumer confidence in the Manuka honey market as a whole. Consumers seeking the healing properties of Manuka honey are being deceived and may not receive the health benefits they are hoping for.

At MNZ, we have a strict policy against such practices. We strive for complete transparency in our manufacturing processes and provide accurate information about the MGO values of our honey. Our integrity is paramount, as we believe that honest practices not only protect the consumer but also uphold Manuka honey’s reputation as a natural wonder. We hope the industry as a whole will embrace these standards so consumers can trust in the quality and integrity of Manuka honey products.

If you have doubts about the authenticity or possible fraud of Manuka honey, it is wise to always ask for test results. This provides assurance that the honey has not been adulterated or heated.

PRODUCTION COSTS VARY CONSIDERABLY, LEADING TO SIGNIFICANT PRICE DIFFERENCES.

Producing Manuka honey is costly and labor-intensive. However, some producers may try to buy up cheap batches of honey from beekeepers who happen to have a large stock and want to get rid of it. One problem that often results from this is that the quality of Manuka honey can vary greatly because it often comes from many different parts of New Zealand, and different regions produce Manuka honey with slightly different characteristics, such as grain size, taste, and color. Furthermore, products claiming to be made in New Zealand may actually only be packaged in Europe, making them no longer true New Zealand honey. Processing the product in Europe may result in less stringent requirements than in New Zealand, resulting in higher processing temperatures. This can negatively affect the quality of the honey.

At MNZ, we emphasize investing in production processes to ensure that the valuable product from our hard-working bees is optimally processed and packaged in New Zealand, going beyond organic guidelines. In this way, we strive for the highest possible quality and integrity of our honey. It is important to note that not all Manuka honey is created equal and that sourcing and processing can have a significant impact on the final quality of the product and, therefore, the price.

At MNZ, we manage the entire process, allowing us to deliver consistent quality.

WHAT IS ACTUALLY CREAM MANUKA HONEY AND ITS DIFFERENCE FROM UNPROCESSED RAW HONEY – UNDERSTAND THE PROCESS.

The process of making cream Manuka honey, also called homogenization, is designed to artificially control the formation of crystals in honey and achieve a smooth and spreadable consistency. Here is what you need to know about this process:

Homogenizing:

Homogenization involves careful mixing of honey to achieve uniformity in structure and composition. In this process, the honey particles are reduced to tiny crystals, usually smaller than 25 microns (0.025 mm), which are evenly distributed. The result is a honey that remains smooth and spreadable for extended periods of time.

Crystallization:

During homogenization, small crystals of “seed honey,” which already contains very fine crystals, are mixed with liquid honey to prevent larger crystal formation. This mixing process is closely controlled and carried out at a temperature of 16-18°C, with the crystals forming naturally.

Heating:

In some cases, honey is heated to temperatures between 40°C and 65°C and held for several days, returning the honey from a crystallized state to fluidity. During this process, the recrystallization process is performed to give the honey an ideal spreadable consistency.

Blending:

Cream Manuka honey is intensively mixed over several days using special machines that combine aeration and mixing. This process creates small crystal centers and prevents further growth of pre-existing crystals.

The result of the homogenization process is a honey with a smooth and creamy texture. The appearance of this honey is different from liquid honey, with a lighter color and less transparency. It is important to note that this process has no harmful effects on the quality of the honey.

Unlike this process, other methods such as pressure filtration and pasteurization are used to process honey, but these can alter honey’s natural properties and remove nutrients. Pasteurization, for example, exposes honey to high temperatures, leading to the loss of nutrients and the destruction of enzymes.

Therefore, it is important to understand how different processing methods can affect the quality and properties of honey so that you can choose the honey that best suits your preferences and needs.

WHAT IS ACTUALLY RAW MANUKA HONEY – UNDERSTAND THE PROCESS.

Raw Manuka honey is exactly as nature intended: pure, unprocessed, unpasteurized, and unheated. Over time, this honey can crystallize, which is actually a natural and beneficial process.

Honey is naturally a highly saturated sugar solution, with more than 70% sugars and less than 20% water. At room temperature, honey contains more dissolved sugar than it can normally hold. In the warm environment of the hive, about 35°C, the sugar in honey remains in dissolved form. But at lower temperatures, the sugars begin to crystallize, making honey solid. This crystallization process preserves the rich flavor and quality of honey.

Some honey crystallizes evenly, while others partially crystallize and form two layers, with a crystallized layer at the bottom of the jar and a liquid layer above. The size of the crystals varies depending on where the honey comes from. The appearance of crystallized honey is different from liquid honey. It becomes lighter in color and less transparent. This is because glucose, one of the main sugars in honey, tends to crystallize earlier than fructose. Glucose crystals are naturally white.

The size of the crystals also depends on where the Manuka honey comes from in New Zealand. Raw Manuka honey is naturally harder than average honey because of its natural properties. If you see white residue or crystallization in raw Manuka honey, do not worry. This is typical of raw honey and actually demonstrates the natural crystallization.

If you gently heat the honey in warm water (up to 35°C), it will liquefy again. Centrifuging is often used when extracting raw honey. This process removes larger wax particles and provides cleaner honey by avoiding impurities and small wax particles. Importantly, during this process, the honey is not exposed to heat, which preserves its natural properties.

Features of raw honey include the preservation of vitamins, minerals, and nutrients, a higher content of natural enzymes, and a rich amino acid profile. Raw honey also has a thicker consistency and slightly grainy texture, providing a unique flavor experience with a delicious aroma.

PACKAGED AND PROCESSED IN NEW ZEALAND

Another crucial aspect is that Manuka honey must be processed and packaged in New Zealand and extensively tested for the presence of natural methylglyoxal (MGO). These criteria are carefully checked by the New Zealand Ministry for Primary Industries (MPI) before the honey leaves the country.

NO GMO – 100% PURE NATURAL

Ensuring the absence of genetically modified organisms (GMOs) in Manuka honey is an important issue, as consumers expect the purity and integrity of the product. Testing Manuka honey for the presence of GMOs and taking steps to destroy any contaminated batches, as is done at MNZ, is a sensible and responsible approach.

WHAT IS GLYPHOSATE (PESTICIDE) AND WHY ONE SHOULD AVOID IT.

Glyphosate, a widely used herbicide in agriculture, is known for its harmful effects on insects. Used to control weeds, this powerful chemical has indirect but devastating effects on insect populations. One of the main reasons glyphosate is harmful to insects is due to the loss of biodiversity. It kills not only weeds but also the wild plants and flowers that serve as food sources and habitats for insects, such as bees and butterflies. As their food sources and habitats decline, insects are forced to look elsewhere for food and shelter, leading to disruptions in their natural behavior and migration patterns.

Moreover, glyphosate has indirect effects on insects by disrupting soil microbial diversity. This affects the quality of crops that insects eat, impacting their health and reproduction. Insects that come into contact with glyphosate residues on plants may also experience direct damage, including loss of orientation, weakening, and mortality.

It is important to emphasize that insects are critical to ecosystems and food production because they provide pollination for crops and serve as a food source for other animals. The harmful effect of glyphosate on insects, therefore, has far-reaching implications for the overall health of our ecosystem and food supply. This highlights the need to carefully consider how we use this chemical and explore alternative methods to control weeds without causing unnecessary harm to insect populations.

HEALTH EFFECTS

Although research is ongoing to further understand the health effects of glyphosate and regulatory agencies are taking steps to manage the risks, concerns about glyphosate raise questions about its safe use and emphasize the importance of taking precautions when exposed to this chemical. It is always advisable to use products containing glyphosate according to the instructions and be aware of potential sources of exposure.

DEALING WITH THE BEES – WHAT YOU NEED TO KNOW!

It is indeed of great importance to honor and appreciate bees for their crucial role in the production of Manuka honey and many other foods that depend on pollination. Bees play a vital role in natural food production and ecosystems, and their labor contributes to biodiversity and the availability of healthy food for humans and animals.

Manuka honey is just one example of how bees contribute to human health and well-being. Their hard work in collecting nectar and pollen, as well as their pollination services, are invaluable to agriculture and the natural world.

It is important to be aware of the challenges facing bee populations worldwide, including factors such as pesticides and habitat loss. Supporting bee-friendly practices and preserving their natural habitats are crucial to protect and maintain bee populations.

Honoring bees and their role in creating nutritious and beneficial products like Manuka honey is not only about respecting nature but also about understanding the delicate balance needed to maintain the health of our planet.

MNZ’s Commitment to Bee Protection and Health

Expert Beekeepers and Inspectors:

As part of our “BeeProtective” program, we have specialized beekeepers and seasonal beekeeping inspectors on New Zealand’s North and South Islands. They look after the health and welfare of our bees.

Placement of Hives:

We manage over 5,600 hives, ranging from large operations to remote areas. These hives are carefully placed in rural and isolated areas with abundant Manuka trees.

Health Inspections:

Our bee protection and health program includes regular inspections of hives and bee colonies. We check for possible pests such as Varroa and Tropilaelaps mites, pathogens such as the fungus Nosema, and other viruses.

Feeding of Bees:

Our bees are fed exclusively on their own honey supply accumulated in their hives during the season. Only in exceptional circumstances, such as very harsh winters, do we provide supplemental feeding.

Quality Control:

We perform strict quality control on our Manuka honey. This includes testing for microbiological elements, toxins, pesticides, sugars, pollen, moisture content, taste, color, and enzyme activity to ensure that our honey is of the highest quality and purity.

Government Regulation:

We comply with regulations from government agencies such as the New Zealand Ministry for Primary Industries (MPI) and the New Zealand Environment Protection Authority (EPA) to ensure bee health and the quality of our honey. This includes rules for the use of insecticides and neonicotinoids.

Minimizing Frequency Emissions:

We ensure that our hives are placed far away from transmission towers and other sources of frequency emissions to minimize their impact on bees.

Manufacturing and Packaging:

Our Manuka honey is produced, processed, and packaged in New Zealand, and we use BPA-free packaging.

All of this is to ensure that our raw, monofloral Manuka honey and honey products are of the highest purity and quality, while protecting the health and well-being of our precious bees.

RADIATION

Growing urbanization and the use of wireless technologies are increasing electromagnetic radiation in urban areas, a potential concern for bees and other flying insects. A recent study used honeybees as a model to examine the effects of long-term exposure to certain RF-EMF frequencies, specifically 2.4 and 5.8 GHz. The results showed that this exposure affected the ability of bees to return to their hive but had no effect on brood development or adult bee longevity. The full study is available here (https://doi.org/10.1016/j.scitotenv.2023.165211).

It is essential to note that in order to raise awareness, people must realize that bees play the most crucial role.

MNZ’s efforts to protect their bees from wireless frequencies reflect their deep commitment to the well-being of bees. They understand that bees need an optimal and undisturbed environment to efficiently forage, collect pollen, and safely return to their nests. MNZ actively avoids proximity to wireless transmission towers and sources to protect bees from potential long-term effects. This proactive approach to beekeeping practices highlights MNZ’s dedication to the well-being of their bee colonies. They strive to create an environment that supports bees in their pollination efforts and overall vitality, and they take preventative measures to preserve the natural instincts and behaviors of their bees.

In an era when wireless technologies are an integral part of our daily lives, MNZ’s commitment to minimizing exposure to wireless frequencies exemplifies their dedication to bee health. Their priority is to provide an optimal and safe environment for their bees while being aware of the potential impact of modern technologies on the delicate balance of ecosystems and the important role of pollinators. MNZ’s commitment to bees goes beyond placing hives; it includes a comprehensive bee protection and health program, strict quality control processes, and compliance with government regulations. By making the protection of their bees from wireless frequencies a priority, MNZ sets an example for other beekeeping organizations and plays an important role in maintaining bee health and sustainability in our natural environment.

With so many different brands and types of Manuka honey, it can be difficult to know which Manuka honey is good and which is not. As a producer of Manuka honey, we find it concerning that there is a lot of fraud that causes people to lose confidence in the product and its health benefits. This is also why we want to educate you on what to look for before buying Manuka honey.